An Overview of MECHATROLINK-4

MECHATROLINK-4 has evolved into a next generation motion field network, while maintaining the high functionality, high performance, high reliability, and usability of its predecessor MECHATROLINK-Ⅲ. MECHATROLINK-4 is a new generation motion field network that incorporates new specifications that have never existed before.

∗ A controller, PLC, or similar device connected to the network is referred to as a “Main Device (abbreviation: MDevice)”. A device such as a servo drive, AC drive, or I/O device is referred to as a “Subordinate Device (abbreviation: SDevice)”.

Features

(1) Streamlining the Transmission Sequence

MECHATROLINK-4 has greatly improved transmission efficiency by switching the communication mode from half duplex to full duplex.

This allows MECHATROLINK-4 to support the creation of systems with improved functionality and higher performance.

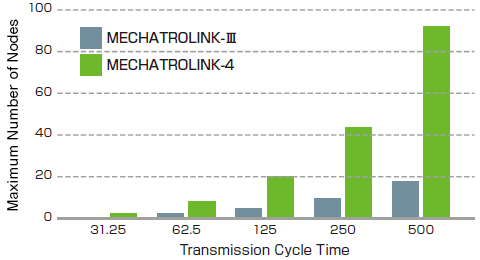

- Improved control performance: The transmission cycle for the same number of devices has been shortened to approximately 1/4 that of the previous version. This achieves more accurate control.

- Support for large-scale systems (equipment): The number of SDevice devices that can be connected to the same transmission cycle is approximately 4 times that of MECHATROLINK-Ⅲ.

- Setting aside the transmission cycle, idle time can be used for Internet protocol, message, and retry communications.s

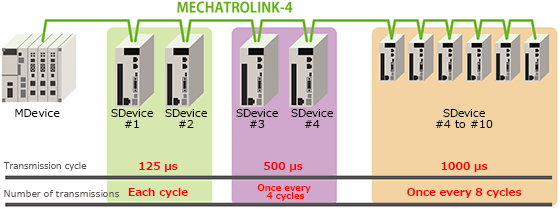

(2) Multiple Transmission Cycles

With MECHATROLINK-4, different cycle settings can be set for each SDevice. Multiple transmission cycles can exist on the same network, allowing SDevice devices to be controlled with the optimal transmission cycle.

- Fast transmission cycles and slow transmission cycles can be set on the same network.

- I/O devices that do not require fast periodic control can be connected to high-speed networks without increasing the communications load.

- More SDevice devices can be connected by distributing the communications timing of devices that communicate using a slow cycle.

- The Controller program can be created more efficiently by setting the optimal transmission cycle for each SDevice.

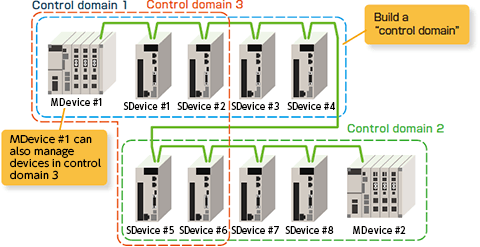

(3) Multiple Control Domain System

MECHATROLINK-4 enables system configurations which allow up to eight MDevices on the same network. Use the multiple control

domain system to improve equipment performance and support safety systems.

- Build logical groups called“ control domains” for each MDevice and the SDevices under its control.

- One MDevice can manage multiple control domains.

- SDevices can belong to multiple control domains.

- Control communications within a control domain can be simultaneously perfomed in parallel. (the Parallel I/O transmission)

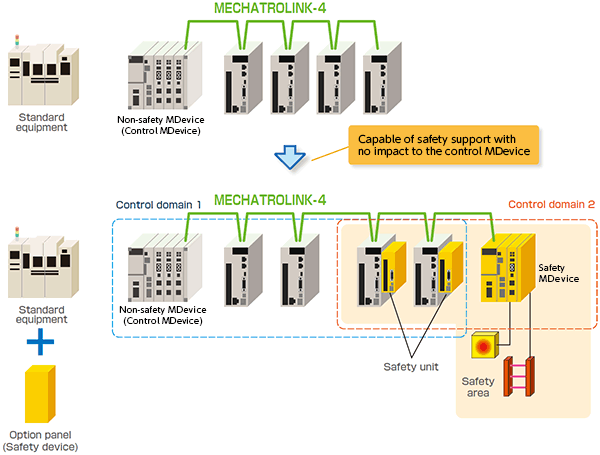

(4) Support for Safety Systems

MECHATROLINK-4 is capable of supporting safety systems by using the multiple control domain system (in the future).

(5) Connections to Ethernet Devices

Ethernet devices can be connected directly to MECHATROLINK-4. Idle bands within the transmission cycle created by improved transmission efficiency are used as Internet protocol bands. Internet protocol bands that are used have no impact on control communications.